Ballpointpenunderscanningelectronmicroscope

Although a small ballpoint pen was ordinary, it was once a difficult problem that faced the Chinese people. We were once mocked for being able to build aircraft carriers, while ballpoint pen heads rely on imports. It was not until 2016 that Taiyuan Iron and Steel Group produced high-performance pen tip specialized steel that China was able to overcome this awkward situation.

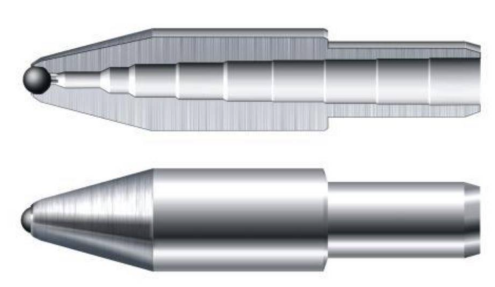

The cross-sectional morphology of the Fe containing sample in Figure 1

The manufacturing of ballpoint pens requires mastering the manufacturing ability of special steel and extremely high precision machining ability at the micron level. It is necessary to ensure a stable supply of ink to the pen tip without exposing the ink, to prevent interruptions and achieve a smooth and long-lasting writing effect.

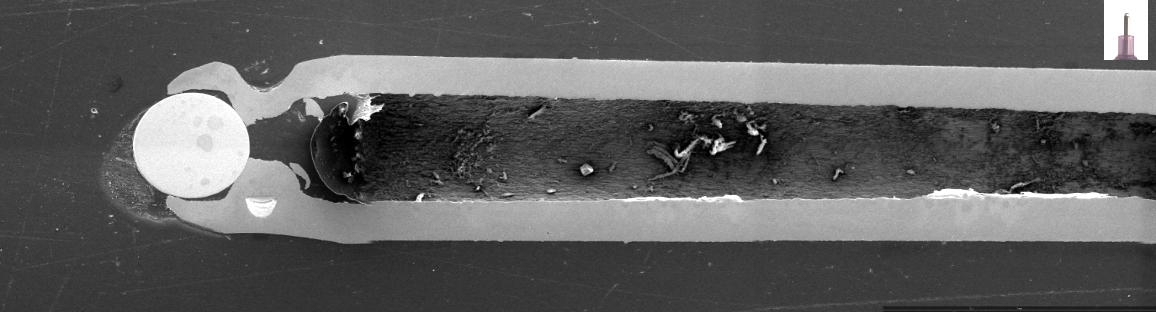

So what are the structures of the ballpoint pens and water-based pen tips we use in our daily lives? We randomly disassembled two pen cores, polished them, and placed them under the Axia ChemiSEM scanning electron microscope to see if there were any differences in their internal structure.

.png)

Figure 2 Internal structure of bullet head and needle tube refills

Ballpoint pens are actually a general term for ballpoint pens, commonly referred to as ballpoint pens and water-based pens, which actually belong to the category of ballpoint pens. They both use the rotation of the ball to achieve the purpose of writing. As shown in Figure 2, the left image shows the bullet tip refill, while the right image shows the needle tube refill. It is evident that the two have different structures.

Generally, bullet tip pen refills are made by cutting a single stick into a complete pen head through metal cutting. This type of ballpoint pen head design generally includes a writing ball and a holding tube, also known as a ball socket. The holding tube is equipped with a ball chamber that can accommodate freely rotating balls, a rear hole, and a guide hole.

The length of the pen head is relatively long, and we can easily obtain the complete morphology of the pen head through the intelligent large-area imaging of Axia ChemiSEM, as shown in Figure 3. (Note: There is a spring inside the ball socket, and some of the larger springs are left on the right side of the cavity due to loss during sample preparation.)

.png)

Figure 3 Large cross-sectional view of bullet tip refills

The needle tube pen core is generally processed by non cutting methods, and before being processed into a pen head, it is a complete thin tube. Use precision instruments to punch N concave points in N directions at the front end of the thin tube to form a bowl seat with ball beads, as shown in Figure 4.

Figure 4 Large cross-sectional view of needle tube refills

The size of the cross-section of this sample was measured as shown in Figure 5, with a ball diameter of 400 μ Above m, and its base needs to ensure both the stability of the ball and the smooth rolling of the ball: if the ball socket is slightly larger, the ball will fall out; If the ball socket is smaller, the ball bead is restricted and cannot write smoothly.

.png)

Figure 5 Pen refill size measurement diagram

At the same time, through Axia's multi-channel imaging and real-time energy spectrum functions, we can simultaneously obtain material morphology and composition information, obtaining a more comprehensive understanding. The interface shown in Figure 6 is for real-time observation. By using dual navigation, the position of the pen core sample can be intuitively found, and its morphology and composition information can be obtained, as shown in Figure 7.

.png)

Figure 6 Axis ChemiSEM multi-channel simultaneous imaging interface

.png)

Figure 7 Real time spectral distribution of pen refills

Ball beads need to withstand long-term pressure and friction, and their material needs to be sturdy, wear-resistant, and stable in nature. The mainstream materials for ball beads in the market are tungsten carbide and specially made stainless steel. Through real-time energy spectrum, we can see that the ball material of these two pen refills is tungsten carbide.

The development of small ballpoint pens from import to localization also reveals that China's manufacturing is moving from extensive to refined development, constantly advancing towards industrial upgrading, and continuously improving international competitiveness. The ballpoint pen core is just a small issue, and we believe that we will continue to break free from various technological blockades, showcase China's technological heritage in material manufacturing and processing, and move forward with great strides.

References

[1] Hong Hong Ballpoint pen core technology solves the dilemma and hope of refracting Chinese manufacturing [J] Vanguard, 2017 (3Z): 2

[2] Ishii Jiaxiu Manufacturing method for ballpoint pen head, ballpoint pen core, ballpoint pen, and ballpoint pen head

[3] https://www.sohu.com/a/657860891_121617550

https://zhuanlan.zhihu.com/p/137574283